Hi heat is a durable enamel formulated

to resist temperatures of up to 350 degrees

celsius.

Hi heat can be used on exhausts,

manifolds and various other heated

applications.

Hi heat does not gloss, but has a velvet finish.

Hi-Heat Black Spray Paint 250ml

R154.00

Hi heat is a durable enamel formulated

to resist temperatures of up to 350 degrees

celsius.

Hi heat can be used on exhausts,

manifolds and various other heated

applications.

Hi heat does not gloss, but has a velvet finish.

SKU:

2570

Categories: Paint Sealers & Primers etc, Spray Paints

Description

Additional information

| Weight | 0.3 kg |

|---|

Reviews (0)

Be the first to review “Hi-Heat Black Spray Paint 250ml” Cancel reply

You must be logged in to post a review.

Related products

Aqua Matt Full Fibre Waterproofing 1Lt

R143.00

DESCRIPTION

Aqua Matt waterproofing has one of the

highest solid, full fibre, content on the

market at almost 60%, forming a paste,

yet paint on consistency product for all

waterproofing needs.

Aqua matt is an acrylic coplymer coating

and is one of the few that, once cured,

can withstand complete submersion in

water.

FEATURES

Aqua Matt creates a high quality,

fibre re-enforced acrylic waterproofing

compound which:

- Is a paste consistence therefore able

to fill gaps and fine cracks.

- Can withstand complete submersion in

water

- Is able to form a seamless water proofing

system with no joints.

- Is easily applied with a paint brush or

roller.

- Is designed specifically for the function

of waterproofing and unless there are two

different substrates where excessive

movement is expected, no waterproofing

membrance is required.

e.g. Parapet walls, window cills or roof

ridging.

- Fillers reduce the temperature underneath

the surface it is applied to by as much as

30%.

- Fillers reduce heat absorption reducing

long term product fatigue.

- Has been designed to stretch and is

water and water-vapour resistant.

- Aqua Matt is off white in colour, and can

be used on its own, or can be coated with

any suitable coating.

AVAILABLE in 1lt, 5lt and 20lt

Cementek UV Clear Liquid Cement Sealer & Hardener 5Lt

R664.00

DESCRIPTION

CEMENTEK is a sealer for cement based

surfaces providing a hard wearing dust free

finish that can withstand traffic, weathering

and Ultra Violet (UV)

CEMENTEK is a combination curing,

sealing, dust-proofing and hardening for

cement and cementitious surfaces - like

your steel floated floors, counter tops and

bathroom wall and floors.

CEMENTEK will adhere to damp surfaces

and also effectively stops rising moisture.

CEMENTEK is clear (not a syrup colour)

and can withstand UV and complete

submersion in water.

CEMENTEK will not yellow with time.

CEMENTEK can be used as a primer

(under new coatings to hold back damp)

or on its own as a semi gloss finish for

your cement finish project.

Can be used in ponds and dams as a

primer (to stop moisture behind our

waterproofing AQUA SEAL) or on its own

as a natural finish.

CEMENTEK is deep penetrating to form

part of your surface, rather than sitting

on top of your surface and is a concrete

densifier as opposed to simply a sealer.

CEMENTEK is a clear coat and cannot

be tinted. Cementek is to be applied

to a prepared new or existing surface.

Should one want to tint or colour the

surface before the application of

Cementek, ONLY our PRISTINA

paint should be used as it is breathable

allowing CEMENTEK to penetrate.

PRISTINA can be applied as a wash

(diluted 1:3 with water onto a pre wet

surface) or on its own (or a combination

of both to create depth to a solid colour)

FEATURES

CEMENTEK allows for:

- Application to damp uncured cement

without the risk of ensuring that the

surface is less than a certain % dry.

Can screed today and apply Cementek

the following day which will give a lighter

look.

- The curing and sealing of concrete is

accomplished at once.

- Can be applied to old or new

cementitious surfaces.

- Penetrates and hardens the surface.

- No etching of the surface required

to ensure sound adhesion.

- CEMENTEK ensures that the

concrete/cement reaches its full Mpa

once cured.

- Hard-wearing of concrete floors. Stops

new concrete floors from dusting.

- Allows to paint within 48 hours of

plastering.

- Excellent water and U.V. protection

CEMENTEK other uses

- To seal bricks, concrete floors and

other porous surfaces.

- As a sealer on damp plaster without

a normal 28-day curing period, before

painting.

- As a sealer on green (not yet cured)

flat deck roofing before waterproofing

allowing the waterproofing to be applied

after 48 hours instead of normal 28-day

curing periods.

COVERAGE

On a steel floated floor, a minimum of

three coats is required (as Cementek

penetrates the surface)

A 1lt, for the three coats will cover

aprox 3 to 4sqm.

A 5lt for the three coats will cover

aprox 15 to 20sqm.

A 20lt for the three coats will cover

aprox 60 to 80sqm.

Rough surfaces will use more product.

Cementek will highlight the surface it is

applied to, and will give a semi gloss

finish. Applying more coats will improve

the sheen.

A fine hair roller (mohair) or similar is

to be used, and product is to be spread.

TAP the roller regulary on its side to

remove product from the core of the

roller to stop line spillage on application.

Allow a minimum of 4 hours curing

between coats.

USEFUL HINTS

One can add white (or other) cement to

your screed topping to get a lighter or

different colour finish.

AVAILABILTY

CEMENTEK is shipped thoughout South

Africa and directly to you at a nominal

R110 per order with a nominal additional

cost for orders over 30kg's.

This fee is applicable to all other

products on our site.

AVAILABLE in 1lt 5lt and 20lt

CEMENTEK makes use of High Aromatic

White Spirits (HAWS) which ensures the

resin is able to penetrate and is soluble

for application.

CLEANING

Clean all equipment with lacquer thinners.

Enviro PRIME (Metal 250hr+ Salt Spray Anti-Corrosive) 1Lt

R239.00

DESCRIPTION

EnviroPrime is a water-based, red oxide in

colour paint used for priming mild steel and

galvanised iron. Enviroprime offers the latest

technology in anti-corrosive additives making

it a Zinc Phosphate free, water based,

non-Toxic anti corrosive steel and galvanised

iron primer that is environmentally friendly

with a Greenstar VOC rating for priming steel.

On prepared mild steel, Enviroprime easily

passes 250 hours of salt spray testing

showing no sign of rust creep from the scribe

line. (Independent test)

At 500 hours, rust creep has started from the

scribe line inward but still showed good overall

protection and adhesion. This makes

Enviroprime a leading water-based

anti-corrosive steel primer in South Africa.

FEATURES

EnviroPrime metal primer is a modified acrylic

bound primer that:

Incorporates various anti-corrosive pigments.

Is used for the priming of structural steel as

well as galvanised iron, combating white and

red rust.

Dries quickly to a hard finish with excellent

adhesion and good acid rain resistance.

Is low in odour while being nontoxic and

environmentally friendly.

AVAILABLE IN

1Lt 5Lt and 20Lt

A 1Lt will cover 10 to 12 sqm per coat

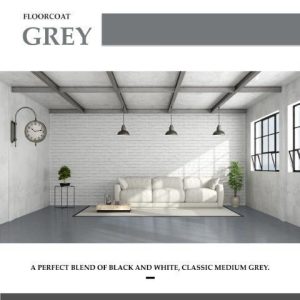

Floor Coat Grey Polyurethane Medium Gloss 1Lt

R184.00

DESCRIPTION

Floor Coat Alkyd Polyurethane Floor Paint

has been formulated for light industrial

concrete floors including for domestic

use. It dries to a tough durable finish

with excellent adhesion.

It is supplied in a range of standard colours

and has a medium gloss finish.

FEATURES

- Tough, durable, thin film floor paint

system.

- Designed to be resistant to most

household chemicals.

- Single pack. (requires no catalyst)

- Excellent stain resistance and easy to

clean.

- Provides a medium gloss finish for

practicality and cleanliness.

- An economical, hard wearing, hygienic,

and fashionable coating.

AREAS OF USE

- Interior concrete floors

- Interior wooden floors

- Interior porous tile floors

SURFACE PREPARATION

EXISTING DRY/CURED UNPAINTED

FLOORS

1. Ensure floor is cured with a moisture

level below 15%. (Do not paint wet floors).

2. Clean floor and degrease if necessary.

(Pink All Purpose Cleaner)

3. Acid wash floor with undiluted acid

(spirits of salt) and rinse well

(immediately) with freshwater. There

must be no acid left on the floor.

Allow to dry.

4. Apply the first coat of FloorCoat DILUTED

10% with mineral turpentine. Allow 6 or

longer hours to dry @ 25 deg C.

5. Apply second coat of UNDILUTED Floor

Coat.

Allow to dry.

USEFUL NOTES

Floor Coat can get traffic after 18hrs, but

will only reach full cure and hardness after

7 days.

With polyurethanes, it is far better to apply

more thin coats than fewer thick coats. Its

important to spread the coat using a short

hair mohair roller.

The viscosity of Floor Coat is designed to

give a melted flow finish, so do not over

work (up and down) on application.

AVAILABLE IN

1Lt and 5Lt

COVERAGE

1Lt will cover 5 to 6 sqm for the two

coats required.

5Lt will cover 25 to 30 sqm for the two

coats required.

Floor Coat Hacienda Polyurethane Medium Gloss 5Lt

R764.00

DESCRIPTION

Floor Coat Alkyd Polyurethane Floor Paint

has been formulated for light industrial

concrete floors including for domestic

use. It dries to a tough durable finish

with excellent adhesion.

It is supplied in a range of standard colours

and has a medium gloss finish.

FEATURES

- Tough, durable, thin film floor paint

system.

- Designed to be resistant to most

household chemicals.

- Single pack. (requires no catalyst)

- Excellent stain resistance and easy to

clean.

- Provides a medium gloss finish for

practicality and cleanliness.

- An economical, hard wearing, hygienic,

and fashionable coating.

AREAS OF USE

- Interior concrete floors

- Interior wooden floors

- Interior porous tile floors

SURFACE PREPARATION

EXISTING DRY/CURED UNPAINTED

FLOORS

1. Ensure floor is cured with a moisture

level below 15%. (Do not paint wet floors).

2. Clean floor and degrease if necessary.

(Pink All Purpose Cleaner)

3. Acid wash floor with undiluted acid

(spirits of salt) and rinse well

(immediately) with freshwater. There

must be no acid left on the floor.

Allow to dry.

4. Apply the first coat of FloorCoat DILUTED

10% with mineral turpentine. Allow 6 or

longer hours to dry @ 25 deg C.

5. Apply second coat of UNDILUTED Floor

Coat.

Allow to dry.

USEFUL NOTES

Floor Coat can get traffic after 18hrs, but

will only reach full cure and hardness after

7 days.

With polyurethanes, it is far better to apply

more thin coats than fewer thick coats. Its

important to spread the coat using a short

hair mohair roller.

The viscosity of Floor Coat is designed to

give a melted flow finish, so do not over

work (up and down) on application.

AVAILABLE IN

1Lt and 5Lt

COVERAGE

1Lt will cover 5 to 6 sqm for the two

coats required.

5Lt will cover 25 to 30 sqm for the two

coats required.

Floor Coat White Polyurethane Medium Gloss 1Lt

R198.00

DESCRIPTION

Floor Coat Alkyd Polyurethane Floor Paint

has been formulated for light industrial

concrete floors including for domestic

use. It dries to a tough durable finish

with excellent adhesion.

It is supplied in a range of standard colours

and has a medium gloss finish.

FEATURES

- Tough, durable, thin film floor paint

system.

- Designed to be resistant to most

household chemicals.

- Single pack. (requires no catalyst)

- Excellent stain resistance and easy to

clean.

- Provides a medium gloss finish for

practicality and cleanliness.

- An economical, hard wearing, hygienic,

and fashionable coating.

AREAS OF USE

- Interior concrete floors

- Interior wooden floors

- Interior porous tile floors

SURFACE PREPARATION

EXISTING DRY/CURED UNPAINTED

FLOORS

1. Ensure floor is cured with a moisture

level below 15%. (Do not paint wet floors).

2. Clean floor and degrease if necessary.

(Pink All Purpose Cleaner)

3. Acid wash floor with undiluted acid

(spirits of salt) and rinse well

(immediately) with freshwater. There

must be no acid left on the floor.

Allow to dry.

4. Apply the first coat of FloorCoat DILUTED

10% with mineral turpentine. Allow 6 or

longer hours to dry @ 25 deg C.

5. Apply second coat of UNDILUTED Floor

Coat.

Allow to dry.

USEFUL NOTES

Floor Coat can get traffic after 18hrs, but

will only reach full cure and hardness after

7 days.

With polyurethanes, it is far better to apply

more thin coats than fewer thick coats. Its

important to spread the coat using a short

hair mohair roller.

The viscosity of Floor Coat is designed to

give a melted flow finish, so do not over

work (up and down) on application.

AVAILABLE IN

1Lt and 5Lt

COVERAGE

1Lt will cover 5 to 6 sqm for the two

coats required.

5Lt will cover 25 to 30 sqm for the two

coats required.

Ruscon New Tech resin bound red rustconverter 20Lt

R1,846.00

Rated 5.00 out of 5

DESCRIPTION

Ruscon New Tech now incorporates the

latest technology developed for rust

conversion.

Formulated to convert rust on mild steel and

galvanised iron into a tough resin coated,

chemically bonded surface, which can be

overcoated without removing rust back to

bright steel. Ruscon New Tech is non-toxic with

a VOC below 5%, making it an easy and

environmetally friendly option.

FEATURES

-It is specially formulated to convert red rust

on mild steel and galvanized iron into a tough

resin coated converted surface which can be

over-coated without removing rust back to bright

steel.

AREAS OF USE

Rusted mild steel or galvanized iron.

SURFACE PREPARATION AND APPLICATION

MILD STEEL AND GALVANISED IRON

1. By wire brush, remove only loose or flaking

rust. It is important not to remove all rust.

2. Wipe the treated area down to remove all dirt

and sanding dust.

3. Apply using a brush, roller or airless spray.

4. Apply one thin, even coat of Ruscon, ensuring

that you cover all rust completely.

Spot prime rust only.

5. Allow 24 hours curing @25C before

overcoating.

APPLICATION EQUIPMENT

Apply by Brush roller or airless spray

CLEANING EQUIPMENT

Clean all equipment with water immediately

after use.

SPREAD RATE

20Lt will cover aprox 240sqm

AVAILABLE IN

1Lt 5Lt and 20Lt

Ruscon New Tech resin bound red rustconverter 5Lt

R548.00

Rated 5.00 out of 5

DESCRIPTION

Ruscon New Tech now incorporates the

latest technology developed for rust

conversion.

Formulated to convert rust on mild steel and

galvanised iron into a tough resin coated,

chemically bonded surface, which can be

overcoated without removing rust back to

bright steel. Ruscon New Tech is non-toxic with

a VOC below 5%, making it an easy and

environmetally friendly option.

FEATURES

-It is specially formulated to convert red rust

on mild steel and galvanized iron into a tough

resin coated converted surface which can be

over-coated without removing rust back to bright

steel.

AREAS OF USE

Rusted mild steel or galvanized iron.

SURFACE PREPARATION AND APPLICATION

MILD STEEL AND GALVANISED IRON

1. By wire brush, remove only loose or flaking

rust. It is important not to remove all rust.

2. Wipe the treated area down to remove all dirt

and sanding dust.

3. Apply using a brush, roller or airless spray.

4. Apply one thin, even coat of Ruscon, ensuring

that you cover all rust completely.

Spot prime rust only.

5. Allow 24 hours curing @25C before

overcoating.

APPLICATION EQUIPMENT

Apply by Brush roller or airless spray

CLEANING EQUIPMENT

Clean all equipment with water immediately

after use.

SPREAD RATE

5Lt will cover aprox 60sqm

AVAILABLE IN

1Lt 5Lt and 20Lt

Reviews

There are no reviews yet.